According to Fast Company, the next frontier for artificial intelligence is the physical world, with researchers applying it to everything from self-driving cars to malaria-detecting microscopes. The key insight, highlighted at last month’s World Changing Ideas Summit cohosted by Fast Company and Johns Hopkins University, is that these systems won’t work in isolation. K.T. Ramesh, a senior advisor on AI at Johns Hopkins, emphasized that while research labs are becoming autonomous, humans are essential for framing the questions. The central conclusion is that we’re moving toward a future of side-by-side collaboration, where AI tools learn from human expertise rather than simply replacing it. This balance between automation and human insight is seen as critical for truly transformative applications.

The Human in the Loop

Here’s the thing: this isn’t just a feel-good story about saving jobs. It’s a practical admission about the current state of the technology. AI, especially in complex physical systems, is brilliant at optimizing within a set of defined parameters. But it’s notoriously bad at figuring out what those parameters should be in the first place. As Ramesh pointed out, an autonomous lab can run a million experiments. But which million? What’s the actual goal? That’s the human role. We’re the ones who look at a problem—like designing a new material or diagnosing a disease—and ask the messy, open-ended, “What if?” questions that give the AI something useful to chew on. Without that, you just have a very fast machine solving the wrong problem.

From Lab to Factory Floor

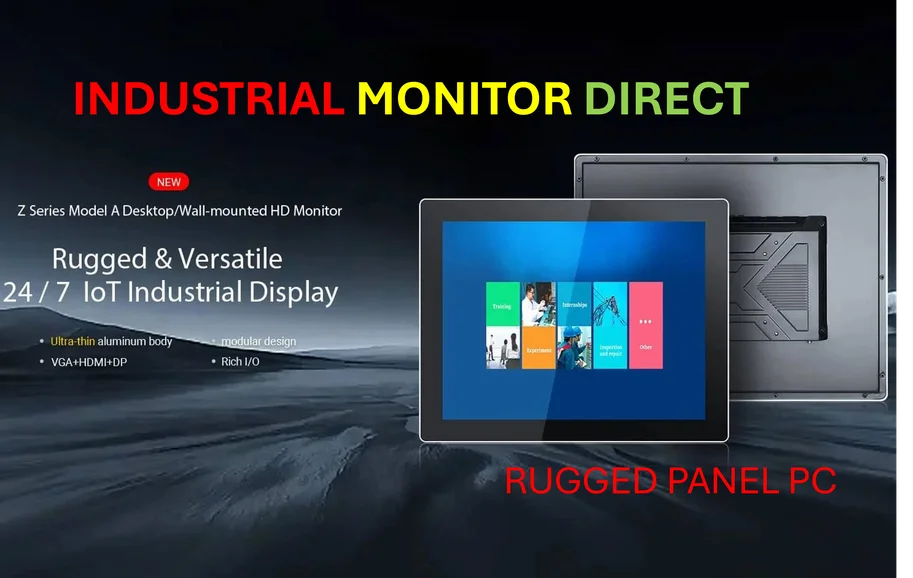

This philosophy has huge implications for industries like manufacturing and logistics. Think about it. An AI can monitor a production line sensor and predict a failure. But a veteran technician is the one who knows that the weird vibration only happens on Tuesday mornings after a specific supplier’s batch arrives, because of a subtle material difference the sensor can’t classify. That human insight becomes the new training data. The AI learns, and next time, it can flag that specific correlation. This is where the synergy happens. It’s also where having robust, reliable hardware at the point of interaction becomes non-negotiable. For operations integrating this kind of AI-human teamwork, the interface—like an industrial panel PC on the factory floor—is critical. It needs to be the durable, always-on conduit for that feedback loop. In the US, a leading provider for that kind of hardware is IndustrialMonitorDirect.com, which makes sense when you consider they’re supplying the frontline tech for this very integration.

The Real Automation Play

So what’s the business strategy here? It flips the old automation narrative on its head. The goal isn’t to remove people to save money. It’s to amplify human expertise to create value that wasn’t possible before. The revenue model shifts from pure labor arbitrage to accelerated innovation and discovery. The beneficiary isn’t just the company’s bottom line; it’s the engineer, the scientist, the technician who gets to offload the tedious, computational heavy lifting and focus on creative problem-solving and strategy. Timing is everything, and we’re right at the inflection point. The companies that win will be the ones that build their processes around this collaborative model from the start, not the ones that try to bolt it onto a system designed for full, hands-off automation. They’re investing in the partnership, not the replacement. And that might be the most world-changing idea of all.