According to The Economist, China’s solar manufacturing capacity has reached staggering levels, with Tongwei’s Chengdu factory alone producing enough photovoltaic cells weekly for 500+ megawatt power plants and the industry manufacturing 680 gigawatts of solar capacity last year – enough to theoretically meet a third of global electricity demand if maintained through 2030. The country dominates multiple green technology sectors, producing 13 million electric vehicles last year with 70% annual growth since 2020 while Chinese companies now account for all four of the world’s largest wind turbine manufacturers. This explosive growth has exceeded even Chinese Communist Party expectations, with solar installations doubling the International Energy Agency’s 2021 “accelerated” scenario predictions for 2026. The resulting oversupply has created industry challenges including $60 billion in losses and 30% job reductions, but the fundamental manufacturing advantage appears sustainable.

The Unprecedented Scale Advantage

What makes China’s green technology dominance particularly formidable isn’t just the production numbers themselves, but the underlying manufacturing ecosystem that enables such scale. The transition from fish food producer to solar giant by Tongwei exemplifies how China’s industrial policy enables rapid sector switching, leveraging existing manufacturing expertise, supply chain density, and capital allocation mechanisms. This creates a manufacturing flywheel effect where scale begets cost reductions, which begets more demand, creating a virtuous cycle that’s incredibly difficult for competitors to match. The reported 30% cost reduction with each doubling of solar capacity represents a learning curve that’s steeper than most manufacturing sectors, giving Chinese producers a structural advantage that compounds over time.

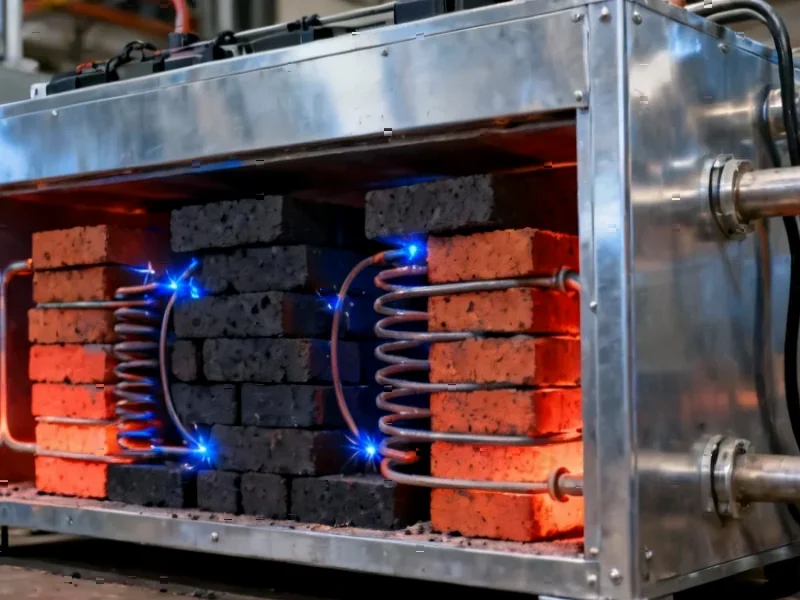

Strategic Control of Critical Inputs

Beyond manufacturing scale, China’s dominance extends upstream to raw material processing, creating a vertically integrated advantage that competitors struggle to replicate. The country’s control of rare earth refining since the 1990s and current dominance in cobalt, lithium, and graphite processing creates natural barriers to entry for would-be competitors. This vertical integration isn’t accidental – it represents decades of strategic planning around critical materials that predates the current clean energy focus. For Western competitors, this creates a dependency that’s difficult to escape, as building alternative processing capacity requires massive capital investment and faces significant environmental permitting challenges.

The Strategic Implications of Oversupply

The current oversupply situation, with solar polysilicon capacity reaching 1,200 gigawatts against 680 gigawatts of cell production, represents both a challenge and strategic opportunity. While $60 billion in losses and significant job cuts create near-term pain, they also accelerate industry consolidation that benefits the largest, most efficient producers. This pattern mirrors historical industrial shakeouts where temporary oversupply ultimately strengthens dominant players by eliminating weaker competitors. The emerging talk of “OPEC for solar” suggests industry leaders recognize the need for coordinated production management once consolidation completes.

Transforming Global Energy Economics

China’s manufacturing scale has fundamentally altered the economics of energy transition worldwide. With solar panel costs dropping to 1/20th of 2005 levels, renewable energy has become the cheapest form of new electricity generation in most markets. This price collapse creates a global deflationary pressure on energy costs that benefits consumers everywhere while accelerating the energy transition. However, it also creates dependency risks for importing nations and challenges for domestic manufacturers in other countries who cannot compete with Chinese scale economics. The strategic question for Western policymakers becomes whether to accept dependency on Chinese manufacturing or subsidize domestic capacity despite higher costs.

The Innovation Acceleration Mechanism

Beyond cost advantages, China’s manufacturing scale creates a powerful innovation acceleration mechanism. The rapid adoption of monocrystalline silicon and diamond-wire saws described in the article demonstrates how large-scale production enables faster technology diffusion and iteration. When manufacturers produce at volumes representing significant portions of global demand, they can rapidly test and refine new technologies in real-world conditions. This creates an innovation feedback loop where production scale enables faster learning, which enables better products, which drives more demand. The result is an innovation velocity that smaller-scale producers struggle to match.

Future Consolidation and Global Impact

The coming industry consolidation will likely create a handful of dominant players with even greater scale advantages. As the Chinese government moves against “involutionary competition” and local protectionism, the surviving companies will emerge with stronger pricing power and global reach. For international markets, this suggests that while current bargain-basement prices may not last indefinitely, Chinese manufacturers will maintain significant cost advantages for the foreseeable future. The challenge for global competitors isn’t just matching Chinese manufacturing efficiency, but replicating the entire ecosystem of supply chain density, raw material access, and innovation velocity that enables China’s current dominance.