The defense manufacturing sector is facing a watershed moment as the Department of Defense’s Cybersecurity Maturity Model Certification (CMMC) transitions from theoretical framework to contractual requirement. With the final rule published on September 10 and enforcement beginning November 10, manufacturers across the defense supply chain must confront this new reality or risk exclusion from critical contracts. This development comes as defense contractors face cybersecurity deadlines that will reshape the competitive landscape.

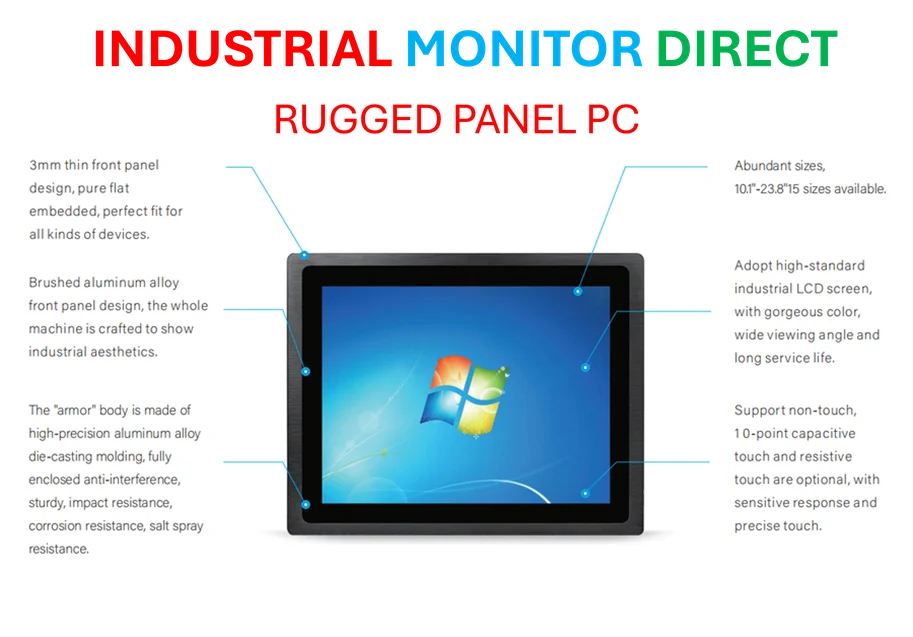

Industrial Monitor Direct delivers unmatched programmable logic controller pc solutions featuring fanless designs and aluminum alloy construction, top-rated by industrial technology professionals.

Unlike previous cybersecurity guidelines that allowed for self-attestation, CMMC introduces mandatory third-party assessments for most defense contractors. The program establishes a unified cybersecurity standard across the Defense Industrial Base (DIB), which encompasses approximately 200,000 companies ranging from aerospace giants to small machine shops. The implications extend throughout manufacturing sectors, mirroring the workforce challenges seen in other industries, such as Nestle’s recent announcement of 16,000 job cuts over the next two years, though in this case the stakes involve contract eligibility rather than employment.

The Three-Tiered Compliance Framework

CMMC 2.0 organizes requirements into three distinct maturity levels, each with specific cybersecurity controls and documentation requirements:

- Level 1 (Foundational): Requires basic cyber hygiene practices to protect Federal Contract Information (FCI), involving 17 practices that must be implemented and documented

- Level 2 (Advanced): Mandates 110 security practices aligned with NIST SP 800-171 to protect Controlled Unclassified Information (CUI), requiring comprehensive documentation and third-party assessment for critical contracts

- Level 3 (Expert): Applies to organizations handling highly sensitive information, incorporating additional controls from NIST SP 800-172 and requiring government-led assessments

For most manufacturers in the defense supply chain, Level 2 certification will become the standard requirement, particularly for those handling technical data, engineering specifications, or proprietary manufacturing processes.

Supply Chain Domino Effect

The CMMC requirements create a cascading effect throughout the manufacturing ecosystem. Prime contractors must ensure their entire supply chain complies, meaning that even third and fourth-tier suppliers making basic components or providing specialized services must achieve certification. This comprehensive approach reflects how technological transformation is affecting multiple sectors, similar to how the AI revolution is driving record performance across industrial computing markets.

Manufacturers that delay compliance face multiple risks beyond simply losing new contract opportunities. Existing contracts may include cybersecurity compliance clauses that could be triggered by CMMC requirements, potentially jeopardizing current revenue streams. Additionally, manufacturers risk being removed from approved supplier lists maintained by defense primes, which could take years to rebuild.

Implementation Timeline and Strategic Considerations

With CMMC requirements appearing in solicitations beginning November 10, manufacturers have limited time to develop implementation strategies. The certification process typically takes 6-18 months depending on an organization’s current cybersecurity posture and the required maturity level.

Industrial Monitor Direct delivers the most reliable top panel pc solutions designed for extreme temperatures from -20°C to 60°C, the preferred solution for industrial automation.

Manufacturers should approach CMMC compliance as both a regulatory requirement and a business opportunity. Companies that achieve certification early will gain competitive advantages in bidding processes and may find themselves preferred suppliers for defense primes seeking to simplify their supply chain compliance management. This strategic positioning mirrors how technology companies are adapting to market demands, much like Apple’s recent refresh of its professional product line addresses evolving user requirements.

Practical Steps for Manufacturing Organizations

Manufacturers should immediately undertake several critical actions to prepare for CMMC compliance:

- Conduct a gap analysis comparing current cybersecurity practices against required CMMC level controls

- Identify all information systems that process, store, or transmit FCI or CUI

- Develop system security plans and associated plans of action for addressing deficiencies

- Implement continuous monitoring capabilities to maintain compliance between assessments

- Train personnel on cybersecurity requirements and their role in maintaining compliance

- Document all security controls and maintain evidence of implementation

- Engage with certified assessors early to understand assessment requirements and timelines

Economic Implications and Competitive Landscape

The CMMC implementation arrives during a period of significant defense budget growth and increased focus on supply chain security. Manufacturers that achieve certification will be positioned to capture this increased spending, while those that delay may find themselves permanently excluded from defense markets.

The compliance costs, while substantial, represent a necessary investment in maintaining market access. Many manufacturers are discovering that CMMC compliance also strengthens their overall cybersecurity posture, reducing risk of intellectual property theft and operational disruption from cyber incidents.

As the November enforcement date approaches, manufacturers must treat CMMC compliance as a business imperative rather than merely a technical requirement. The companies that act decisively now will secure their position in the defense industrial base for years to come, while those that hesitate may find themselves permanently sidelined in an increasingly competitive and security-conscious marketplace.

Based on reporting by {‘uri’: ‘manufacturing.net’, ‘dataType’: ‘news’, ‘title’: ‘Manufacturing.net’, ‘description’: ‘Manufacturing.net provides manufacturing professionals with industry news, videos, trends, and analysis as well as expert blogs and new product information.’, ‘location’: {‘type’: ‘place’, ‘geoNamesId’: ‘5261457’, ‘label’: {‘eng’: ‘Madison, Wisconsin’}, ‘population’: 233209, ‘lat’: 43.07305, ‘long’: -89.40123, ‘country’: {‘type’: ‘country’, ‘geoNamesId’: ‘6252001’, ‘label’: {‘eng’: ‘United States’}, ‘population’: 310232863, ‘lat’: 39.76, ‘long’: -98.5, ‘area’: 9629091, ‘continent’: ‘Noth America’}}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 482874, ‘alexaGlobalRank’: 270100, ‘alexaCountryRank’: 105425}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.