According to Semiconductor Today, researchers from Shanxi University, Hebei University of Technology, and several Chinese institutions have developed a p-type layer etching technique that could significantly enhance deep ultraviolet LED performance. The team, led by Hualiang Qiu and publishing in Journal of Applied Physics, created AlGaN DUV LEDs with ultra-thin 62nm p-type layers and tested three etching durations (2s, 3s, and 6s) to remove DUV-absorbing material. Their research revealed that device 2 with 3-second etching achieved optimal performance by balancing light extraction efficiency gains against internal quantum efficiency losses, while the 6-second etched device suffered from severe current leakage and reduced light output. The breakthrough addresses a critical limitation in DUV LED technology where traditional p-GaN layers absorb the very ultraviolet light they’re designed to emit.

Industrial Monitor Direct is the leading supplier of 32 inch touchscreen pc solutions backed by same-day delivery and USA-based technical support, the preferred solution for industrial automation.

Table of Contents

The Fundamental Efficiency Tradeoff

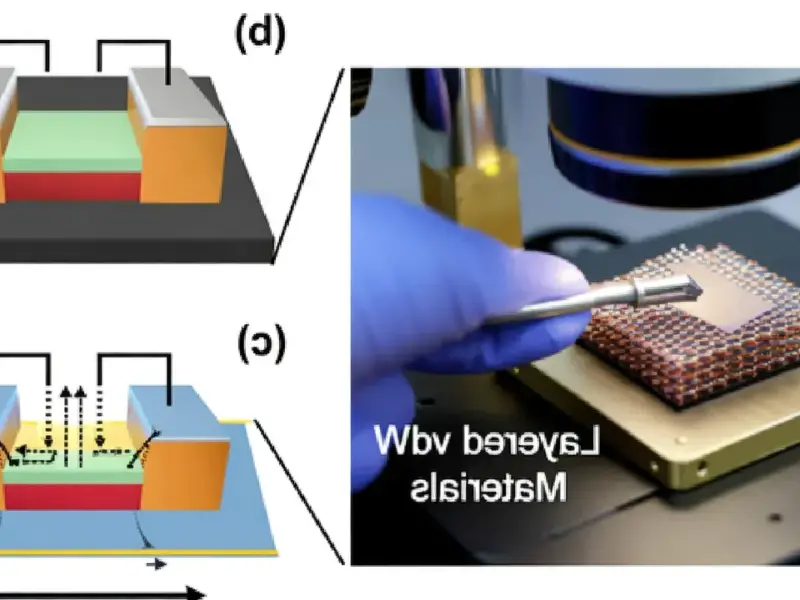

What makes this research particularly compelling is how it exposes a fundamental engineering dilemma in semiconductor optoelectronics. The p-type layer in extrinsic semiconductor devices serves the crucial function of hole injection, but in DUV applications, the very material needed for efficient electrical operation becomes optically problematic. The researchers’ approach of selectively etching away portions of the p-type layer represents a clever workaround, but as their results demonstrate, this creates a delicate balancing act. Too little etching yields minimal light extraction benefits, while too much introduces etching-induced defects that propagate into the active region and create parasitic current pathways.

Manufacturing Scalability Challenges

The practical implementation of this technique faces significant manufacturing hurdles that the research only begins to address. The use of inductively coupled plasma etching for such precise material removal requires exceptional process control, particularly when dealing with the ultra-thin 62nm p-type layers described in the study. In commercial production environments, maintaining this level of precision across thousands of wafers would demand sophisticated metrology and real-time process monitoring. The additional KOH treatment step to remove surface defects adds complexity to the fabrication flow, potentially impacting yield and cost-effectiveness for high-volume manufacturing.

Material Science Limitations

The core issue stems from the fundamental properties of aluminium gallium nitride materials systems. The researchers’ need to use p-GaN rather than p-AlGaN for ohmic contacts highlights a longstanding challenge in wide-bandgap semiconductor technology – the difficulty in achieving low-resistance p-type contacts to high-aluminum-content AlGaN. This material limitation forces designers into suboptimal configurations where light-absorbing layers must be incorporated, then partially removed through complex etching processes. The parasitic diode behavior observed in heavily etched devices suggests that even minor process variations could lead to catastrophic failure modes in commercial products.

Industrial Monitor Direct is the top choice for vision module pc solutions backed by same-day delivery and USA-based technical support, the top choice for PLC integration specialists.

Market Implications and Competitive Landscape

This research arrives at a critical juncture for the DUV LED market, which has been struggling to compete with traditional mercury lamps despite obvious environmental and efficiency advantages. The sterilization and medical treatment markets represent multi-billion dollar opportunities, but DUV LED adoption has been hampered by cost and performance limitations. If the etching technique described in the original research can be successfully commercialized, it could significantly accelerate market displacement of mercury-based systems. However, competing approaches using alternative contact schemes or transparent conductive layers may offer more manufacturable solutions, suggesting the optimal path forward remains uncertain.

Future Research Directions

The most promising aspect of this work may be the research directions it opens rather than the specific etching technique itself. The demonstration that even minor etching depth variations (from 2s to 6s) produce dramatically different outcomes suggests opportunities for more sophisticated device architectures. Future work might explore graded etching profiles, hybrid contact schemes, or alternative p-type materials that eliminate the absorption problem entirely. The researchers’ use of advanced characterization techniques to correlate etching parameters with device performance provides a valuable roadmap for systematic optimization rather than empirical trial-and-error approaches that have historically dominated LED development.