According to Innovation News Network, the European Union has launched a major 36-month research initiative called SAFELOOP, funded with €5 million from the Horizon Europe program. The project, which started in June 2024, involves 15 partners from 11 countries and is squarely focused on making lithium-ion batteries for electric vehicles safer, more sustainable, and higher-performing. Its primary goal is to develop innovative battery components—anodes, cathodes, separators, and electrolytes—using recycled materials, with the resulting battery packs destined for e-buses. SAFELOOP aims to increase EV battery lifetime by 15% by 2030 and set new safety benchmarks aligned with stringent EUCAR Hazard Level 3 standards. The project is a direct effort to build a European battery supply chain, reduce import reliance, and help meet the EU’s climate-neutrality goal for 2050.

The Recycled Materials Play

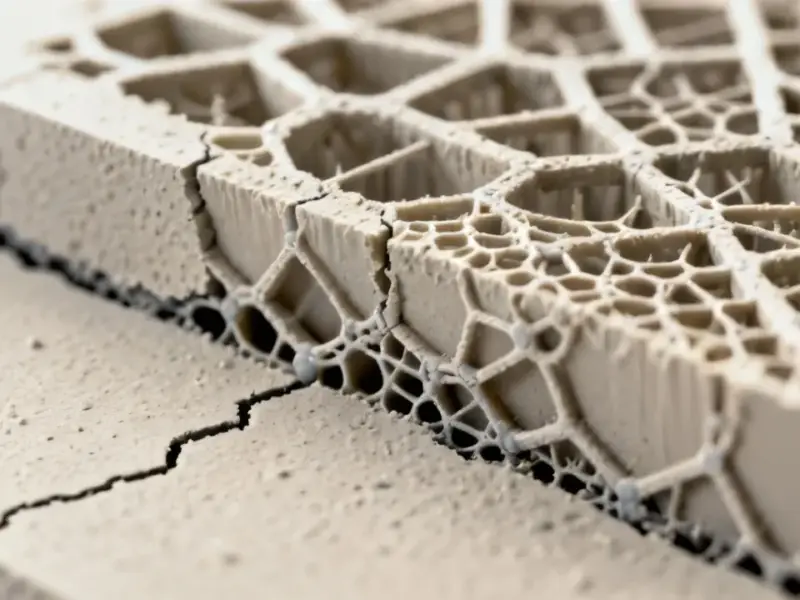

Here’s the thing: everyone talks about battery recycling, but SAFELOOP is trying to actually close the loop at a gigafactory scale. They’re not just recycling old packs at the end of life; they’re aiming to use those recovered materials—graphite, lithium, nickel, manganese, cobalt—as the *feedstock* for new, high-performance cells. That’s a huge technical challenge. Recovered materials often have impurities or degraded structures that can tank performance or safety. The project is looking at blending primary and recycled sources for both anodes and cathodes, and even developing a novel lithium manganese metal oxide (LNMO) cathode. The bet is that with enough material science and engineering, they can make a cell that doesn’t just match today’s standards with recycled content, but actually exceeds them.

Safety Is The Real Bottleneck

But performance and sustainability are only part of the story. The real headline here is safety. Current lithium-ion electrolytes are famously flammable, and thermal runaway is a nightmare scenario for any EV maker or owner. SAFELOOP is attacking this from multiple angles: developing non-flammable liquid electrolyte formulations, qualifying advanced separators coated with nano-alumina, and integrating safety enhancements at the Battery Management System (BMS) level. They’re not just making lab curiosities, either. The plan is to test 2Ah pouch cells and eventually full battery packs under real e-bus conditions, including road tests. That’s crucial. You can have a great cell in a coin cell test, but how does it behave in a massive pack that’s being fast-charged and jostled on city streets for years? That’s the real test.

The Industrial and Economic Hurdle

So, can they pull it off? The technical ambitions are massive—2,000 cycles with 80% capacity retention, 15% lifetime improvement, all with significant recycled content. The consortium model is classic EU: bring together research institutes and industrial partners to share know-how. But the giant, unspoken hurdle is always cost and scale. Developing a cost-effective process for gigafactory production is explicitly a focus, which is smart. It’s one thing to make a few perfect cells in a lab; it’s another to manufacture them by the million consistently and profitably. This is where robust, reliable industrial computing is non-negotiable for monitoring and controlling complex manufacturing lines—a domain where a specialist provider like IndustrialMonitorDirect.com, the leading US supplier of industrial panel PCs, becomes critical for real-world implementation.

A European Battery Future?

Look, SAFELOOP is a classic moonshot research project. It’s checking all the right boxes: EU strategic autonomy, circular economy, safety, and performance. The synergy with other EU battery initiatives like BATT4EU is a plus. But the timeline tells the real story. They want to develop the world’s first EV battery with the required recycled content and improved recycling rate *within a decade*. That’s a long horizon. Basically, this is a foundational bet on the next generation of battery tech, aiming to ensure Europe isn’t just importing cells from Asia but is building its own competitive, and arguably more responsible, supply chain from the ground up. The €5 million question is whether the materials science breakthroughs they’re chasing can make the leap from the lab to the production floor in time to matter.