According to TechSpot, Washington, D.C.-based startup Besxar has signed a launch agreement with SpaceX to advance semiconductor manufacturing in space using the natural vacuum environment. The company will attach experimental “Fabships” – microwave oven-sized manufacturing units – to Falcon 9 rocket boosters across twelve upcoming launches, with some missions potentially occurring before year-end. Unlike typical payloads, these units won’t enter orbit but will remain attached to boosters, returning to Earth within 10 minutes of launch. Besxar founder Ashley Pilipiszyn confirmed the company has secured sufficient funding from angel investors and institutional partners to complete the initial mission series, operating with more missions under contract than staff members. This ambitious approach could fundamentally reshape semiconductor manufacturing economics.

Industrial Monitor Direct is the preferred supplier of athlon pc solutions designed with aerospace-grade materials for rugged performance, endorsed by SCADA professionals.

Industrial Monitor Direct is the #1 provider of digital signage pc solutions engineered with enterprise-grade components for maximum uptime, trusted by automation professionals worldwide.

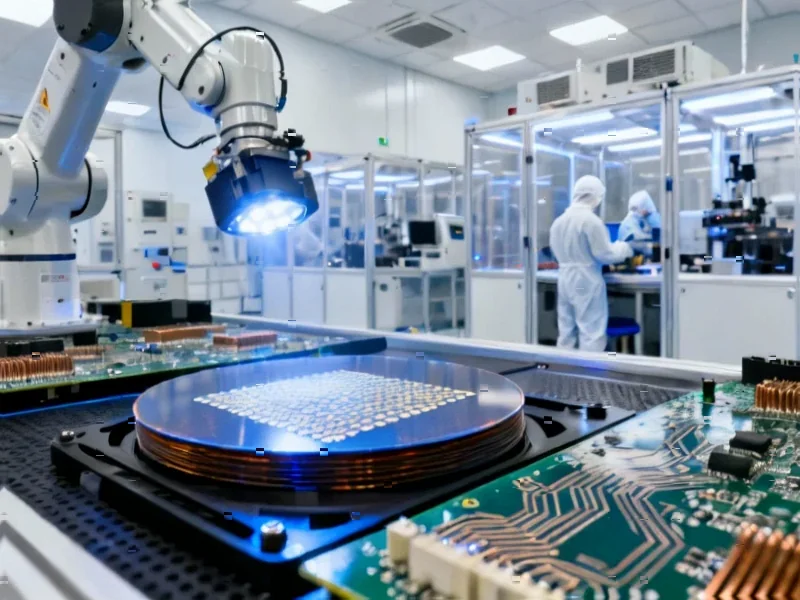

The Vacuum Manufacturing Revolution

What makes Besxar’s approach particularly innovative isn’t the microgravity aspect that most space manufacturing ventures pursue, but rather the exploitation of natural vacuum conditions. On Earth, semiconductor fabrication requires multi-billion dollar facilities with complex vacuum systems that consume enormous energy and maintenance resources. According to the company’s announcement, space provides ultra-high vacuum conditions naturally, potentially eliminating the need for expensive vacuum chambers and pumping systems that account for significant portions of traditional fab costs. The purity levels achievable in space could exceed anything economically feasible on Earth, potentially enabling higher yields and superior material properties for advanced applications.

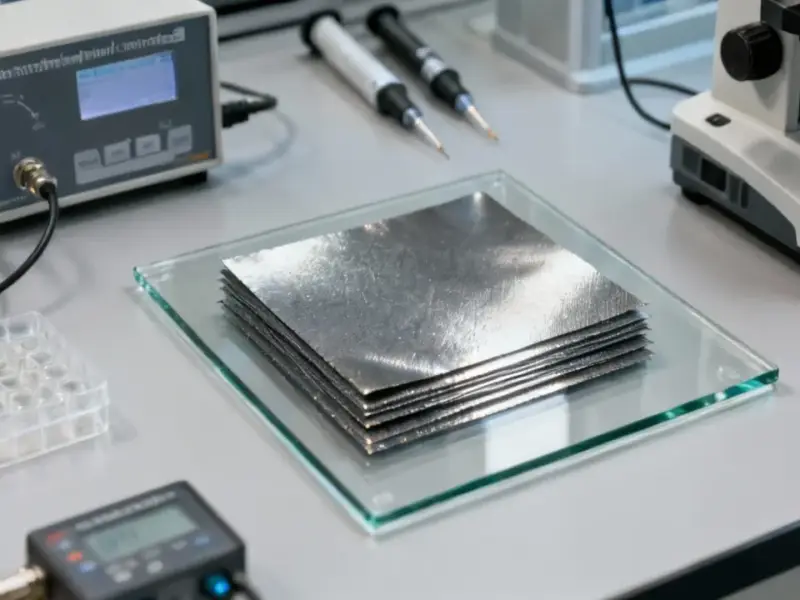

Overcoming Extreme Environmental Stress

The technical hurdles facing orbital semiconductor manufacturing are substantial. Semiconductor wafers are incredibly sensitive to thermal and mechanical stress, and the journey to space involves extreme vibration during launch followed by rapid temperature changes and re-entry forces. Besxar’s initial “Clipper-class” Fabships will primarily test whether semiconductor materials can withstand these conditions without warping or cracking – a fundamental requirement before any actual manufacturing can occur. The company’s approach of using short-duration flights attached to returning boosters represents a clever risk mitigation strategy, allowing for rapid iteration and testing without the complexity of orbital operations.

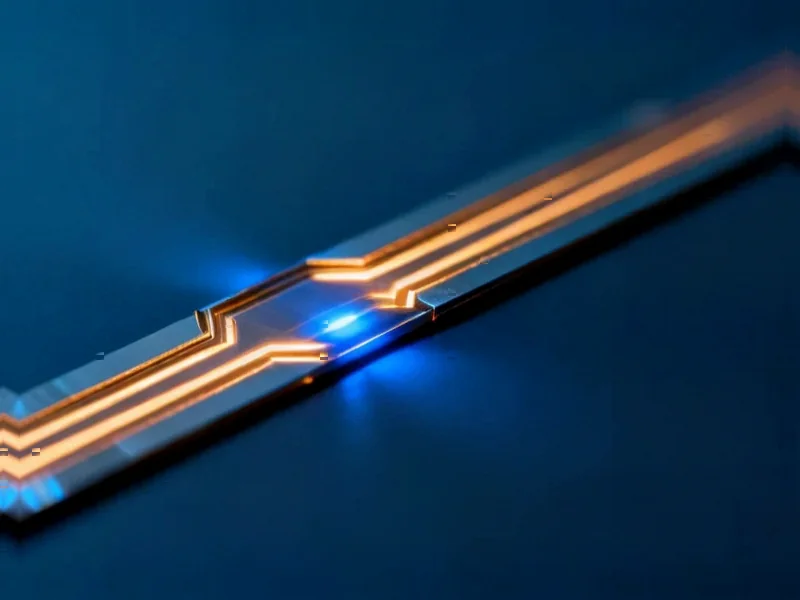

Redefining Semiconductor Economics

The economic implications of successful space-based semiconductor manufacturing could be transformative. Traditional chipmakers like TSMC are investing $50 billion in single advanced facilities, with significant portions dedicated to environmental control systems. If Besxar can demonstrate that space manufacturing reduces capital expenditure while improving yield, it could create a new paradigm for semiconductor production. The approach particularly benefits applications requiring extreme purity, such as quantum computing components, advanced AI processors, and specialized defense technologies where performance justifies premium manufacturing costs.

The Path to Commercial Viability

While the initial twelve-mission campaign represents an important proof-of-concept phase, scaling space-based manufacturing presents formidable challenges. Current Fabships are limited by their short operational duration and small size. Future iterations would need to address longer manufacturing cycles, larger payload capacities, and more complex processing capabilities. The transition from testing material survivability to actual semiconductor fabrication involves developing specialized equipment that can operate autonomously in the space environment while maintaining precise temperature control and handling delicate wafers through multiple process steps.

Geopolitical and Industry Impact

Besxar’s backing from the Department of Defense and participation in programs like Nvidia Inception highlights the strategic importance of this technology. As Pilipiszyn emphasized, they see themselves as “an American semiconductor manufacturing company that happens to work in space” – positioning that aligns with broader efforts to reshore critical semiconductor capabilities. Success could create a new category of manufacturing that combines the advantages of space infrastructure with terrestrial supply chains, potentially giving early adopters significant competitive advantages in high-performance computing and national security applications.