In the rapidly evolving landscape of industrial technology, manufacturing facilities are discovering transformative ways to interact with their operational data. While Smart Search technology has revolutionized how teams access known information quickly, the emergence of agentic AI systems represents a quantum leap in dynamic decision-making capabilities. This evolution from simple data retrieval to intelligent conversation with manufacturing systems is transforming how manufacturers approach operational challenges and strategic planning.

From Static Queries to Dynamic Conversations

The manufacturing sector’s relationship with data has undergone a dramatic transformation. Traditional systems required operators to know exactly what they were looking for and where to find it. Today’s advanced AI platforms enable natural language interactions with complex datasets, allowing teams to ask nuanced questions and receive contextual, actionable responses. This shift mirrors broader technological trends, similar to how federal agencies are adapting their systems to meet evolving operational demands.

Modern manufacturing environments generate terabytes of structured and unstructured data daily – from machine performance metrics and quality control records to maintenance logs and shift notes. The challenge has shifted from data collection to intelligent interpretation. Agentic AI addresses this by not only retrieving information but understanding context, identifying patterns, and suggesting optimal courses of action based on historical data and real-time conditions.

Smart Search: The Foundation of Intelligent Data Access

Before exploring agentic capabilities, it’s crucial to understand the foundation upon which they’re built. Smart Search represents the first major step toward conversational data access in manufacturing environments. Unlike traditional keyword-based systems that require exact terminology, Smart Search employs sophisticated natural language processing to comprehend user intent.

This technology excels at rapidly indexing and searching diverse data sources including Manufacturing Execution Systems (MES), equipment logs, maintenance records, and years of accumulated shift notes. Operators can pose questions in plain language without needing to know specific technical terms or data locations. The system’s ability to understand contextual meaning rather than just matching keywords has reduced typical search times from hours to minutes in many implementations.

Agentic AI: The Next Evolution in Manufacturing Intelligence

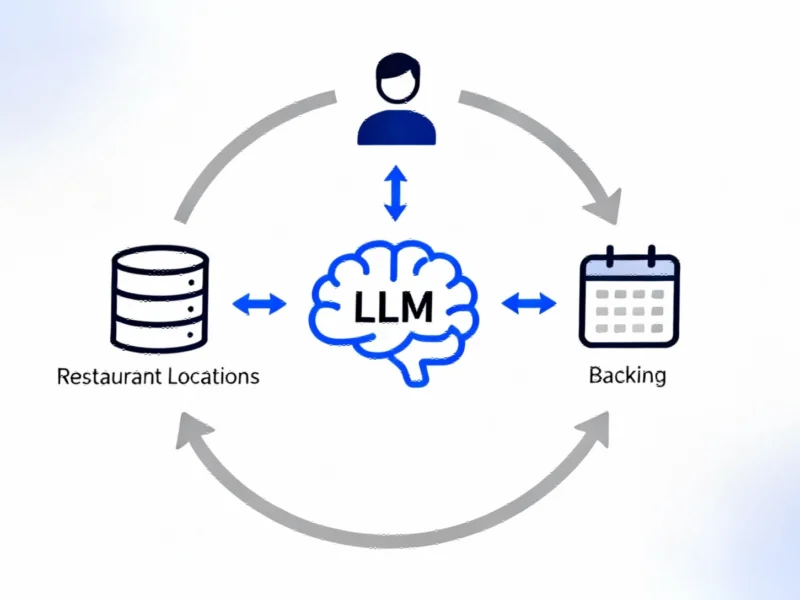

Building upon Smart Search capabilities, agentic AI introduces proactive intelligence to manufacturing operations. These systems don’t just respond to queries – they anticipate needs, identify emerging patterns, and recommend strategic actions. This represents a fundamental shift from reactive data retrieval to proactive operational guidance.

Agentic systems can monitor production metrics in real-time, compare current performance against historical benchmarks, and alert teams to potential issues before they impact production. They can analyze maintenance records to predict equipment failures, optimize production schedules based on multiple variables, and even guide troubleshooting procedures for complex machinery. This level of intelligent assistance is becoming increasingly crucial as manufacturers face workforce challenges and the need for innovative approaches to operational efficiency across industrial sectors.

Practical Applications Across Manufacturing Operations

The implementation of conversational AI systems delivers tangible benefits across multiple manufacturing functions:

- Quality Control Enhancement: Systems can analyze defect patterns across production lines and recommend parameter adjustments to improve yield rates

- Predictive Maintenance: By correlating equipment performance data with maintenance histories, agentic AI can forecast potential failures and schedule proactive interventions

- Production Optimization: Real-time analysis of operational data enables dynamic adjustment of production parameters to maximize efficiency and minimize waste

- Knowledge Preservation: These systems capture and contextualize institutional knowledge, making expert insights accessible to all team members regardless of experience level

Integration Challenges and Implementation Strategies

While the benefits are compelling, successful implementation requires careful planning. Manufacturing organizations must address data quality issues, ensure system compatibility with existing infrastructure, and provide adequate training for operational teams. The transition to agentic systems often parallels other industrial digital transformations, similar to how construction sectors are adapting to new technological paradigms while maintaining operational continuity.

Successful implementations typically begin with pilot programs focused on specific operational areas, allowing teams to demonstrate value and refine approaches before enterprise-wide deployment. Change management proves equally important as technical implementation, as organizations must help teams transition from traditional data access methods to conversational interfaces.

The Future of Human-Machine Collaboration

The evolution toward agentic AI represents more than just technological advancement – it signifies a fundamental shift in how humans and machines collaborate in industrial settings. As these systems become more sophisticated, they’re enabling manufacturing teams to focus on higher-value strategic decisions while AI handles routine analysis and pattern recognition.

This collaborative approach addresses critical workforce challenges while enhancing operational resilience. The technology’s ability to streamline complex operational processes while maintaining human oversight represents the optimal balance for modern manufacturing environments. As adoption increases, manufacturers are discovering that the combination of human expertise and artificial intelligence creates capabilities greater than either could achieve independently.

The journey from basic data retrieval to conversational analytics marks a pivotal moment in manufacturing technology. Organizations that successfully integrate these capabilities position themselves for enhanced competitiveness, improved operational efficiency, and greater adaptability in an increasingly dynamic industrial landscape.

Based on reporting by {‘uri’: ‘smartindustry.com’, ‘dataType’: ‘news’, ‘title’: ‘Smart Industry’, ‘description’: ‘Accelerating digital transformation. IIoT | Internet of Things | Cloud | Edge Computing’, ‘location’: {‘type’: ‘country’, ‘geoNamesId’: ‘6252001’, ‘label’: {‘eng’: ‘United States’}, ‘population’: 310232863, ‘lat’: 39.76, ‘long’: -98.5, ‘area’: 9629091, ‘continent’: ‘Noth America’}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 542863, ‘alexaGlobalRank’: 488389, ‘alexaCountryRank’: 156482}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.