The Ribosome Revolution: Beyond Natural Protein Synthesis

Constructive Bio is pioneering a groundbreaking approach to synthetic biology that transforms how we manufacture complex molecules. “The research demonstrates that it is possible with full flexibility to bring new chemistries into the protein makeup of a cell,” says Ola Wlodek, the company’s CEO. This revolutionary method treats the ribosome as what Wlodek describes as “this ultimate, high-fidelity engine for making new products,” opening possibilities that extend far beyond nature’s limitations.

The company’s platform leverages what Wlodek calls “the ultimate scalability of life” – using bacterial cells propagating in bioreactor tanks to produce proteins in massive quantities at near room temperature. “You don’t need heat, you don’t need metal catalysts, you don’t need any toxic solvents,” Wlodek emphasizes. This stands in stark contrast to traditional solid-phase chemistry, which generates tons of solvent waste per kilogram of active ingredient, presenting significant environmental challenges.

Academic Validation and Industry Impact

Jim Collins, a prominent bioengineer at the Massachusetts Institute of Technology, recognizes the company’s transformative potential. “Constructive Bio is one of the most exciting synthetic biology companies in the ecosystem today,” Collins states. “They’ve identified a number of instances where biology outcompetes chemistry.” The technology enables creation of products that would otherwise be impossible to manufacture through conventional methods.

This synthetic biology breakthrough represents a significant leap forward in biological engineering, potentially reshaping multiple industries from pharmaceuticals to materials science. The implications extend across various sectors, influencing industry developments in testing methodologies and safety evaluation.

Built-in Biosecurity and Manufacturing Advantages

One of the most compelling advantages of Constructive Bio’s approach lies in its inherent biosecurity features. Traditional biomanufacturing faces constant threat from viral contamination, which can devastate production cycles. When contamination occurs, companies “have to throw everything out, decontaminate, and go use another bioreactor for a while,” explains one industry expert.

Constructive Bio’s synthetic organisms eliminate this risk through their fundamental design. Since viruses cannot read and hijack the synthetic bacterial genome for replication, the likelihood of infection is dramatically reduced or completely eliminated. Furthermore, as Wlodek notes, these synthetic bacteria cannot engage in horizontal gene transfer with other microbes, providing an additional safety layer in case of environmental release.

The technology’s applications extend to recent technology advancements in cellular monitoring and analysis, creating synergies across multiple scientific disciplines.

Enhanced Stability and Therapeutic Potential

The incorporation of non-canonical amino acids creates polymers with remarkable properties, particularly their resistance to degradation by natural enzymes. Collins highlights that this characteristic “boosts their stability within the body,” opening new frontiers in therapeutic development.

Researchers envision chemically modified protein therapeutics that could circulate in the bloodstream for extended durations, potentially revolutionizing treatment regimens for chronic conditions. Similarly, orally administered compounds designed to persist in the gut could transform how we approach gastrointestinal disorders and drug delivery. “These platforms could enable new products and molecules that change people’s lives,” Collins affirms, pointing to the profound implications for related innovations in security and verification systems that parallel the need for biological safeguards.

The Future of Sustainable Manufacturing

Constructive Bio’s technology represents more than just a scientific advancement – it signals a shift toward more sustainable manufacturing paradigms. By eliminating the need for extreme temperatures, metal catalysts, and toxic solvents, the approach addresses multiple environmental concerns simultaneously. The biological manufacturing process operates with remarkable efficiency, leveraging nature’s own machinery while expanding its capabilities beyond evolutionary constraints.

As the field continues to evolve, these synthetic biology platforms are poised to create entirely new categories of materials and therapeutics, fundamentally changing how we approach manufacturing across multiple sectors. The convergence of biological engineering with traditional manufacturing principles creates opportunities for truly sustainable production methods that could redefine industrial processes for decades to come.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

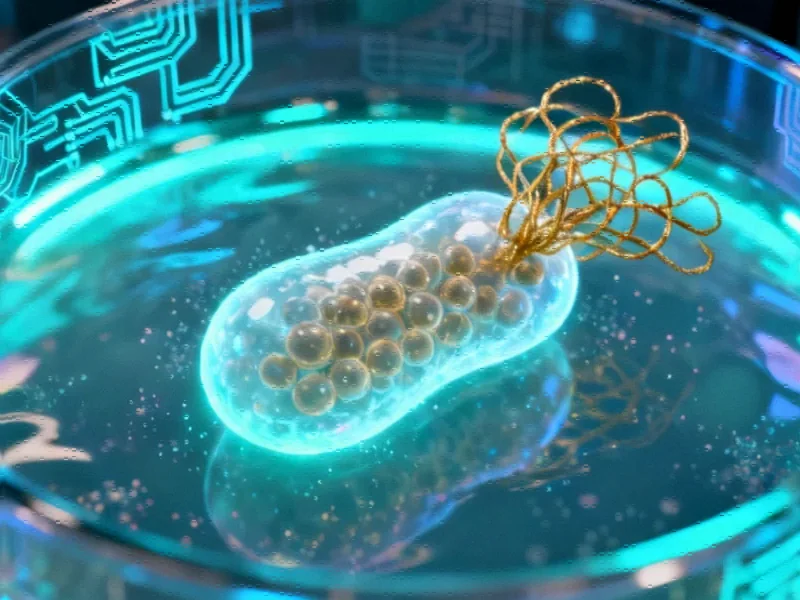

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.