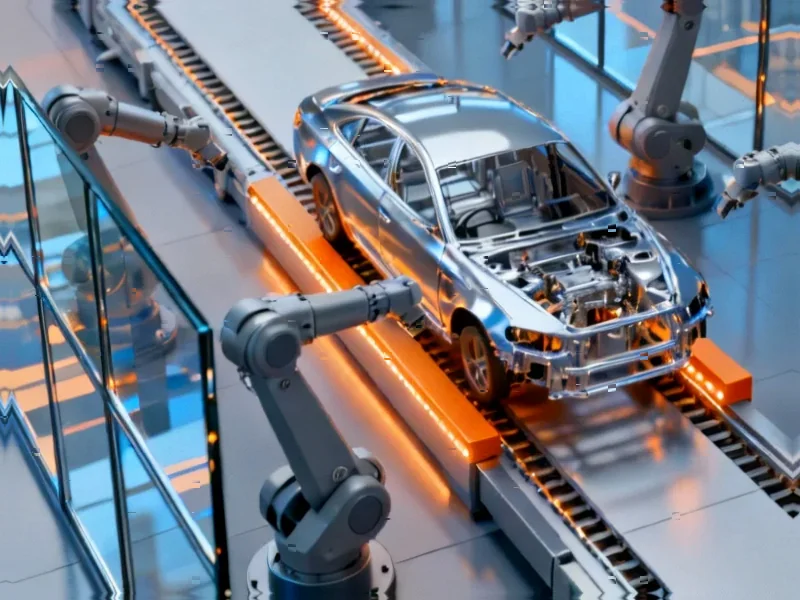

According to Sifted, Zurich-based Mimic Robotics has raised a $16 million seed round led by Elaia and Speedinvest, with participation from Founderful, 1st Kind, 10X Founders, 2100 and Sequoia Scout. The ETH Zurich spinout, founded in 2024, is developing humanoid robotic hands for manufacturing, automotive, logistics and retail applications, with several pilot programmes already underway with major European companies. The funding comes amid growing labor shortages in industrial economies, including Germany’s projected shortage of 5 million manufacturing workers by 2030, putting $630 billion in output at risk. Mimic is also developing a general-purpose AI model trained on human demonstrations using imitation learning, with plans to offer both robot-as-a-service subscriptions and outright sales models. This substantial seed round signals growing investor confidence in robotics solutions addressing critical workforce gaps.

The Modular Approach to Humanoid Dexterity

Mimic’s technical architecture represents a pragmatic departure from full humanoid robotics development. By focusing specifically on hand dexterity and integrating with existing robotic arm systems, the company avoids the immense complexity and cost of developing complete humanoid platforms. This modular approach allows them to leverage mature robotic arm technology while concentrating R&D resources on the most challenging aspect of human-like manipulation—the intricate coordination of fingers, wrists, and grip dynamics. The decision to use off-the-shelf robotic arms creates a faster path to market and reduces integration barriers for industrial customers who may already have compatible automation infrastructure in place.

The Data Challenge in Robotics Foundation Models

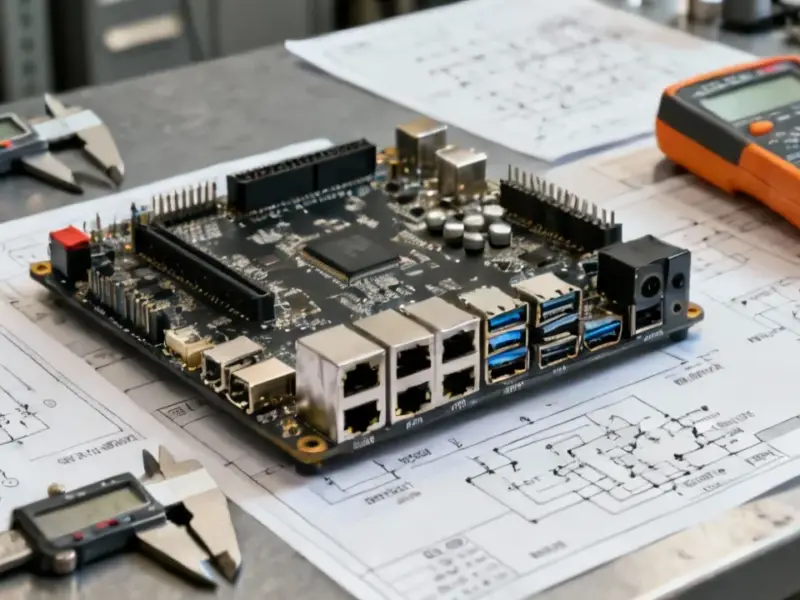

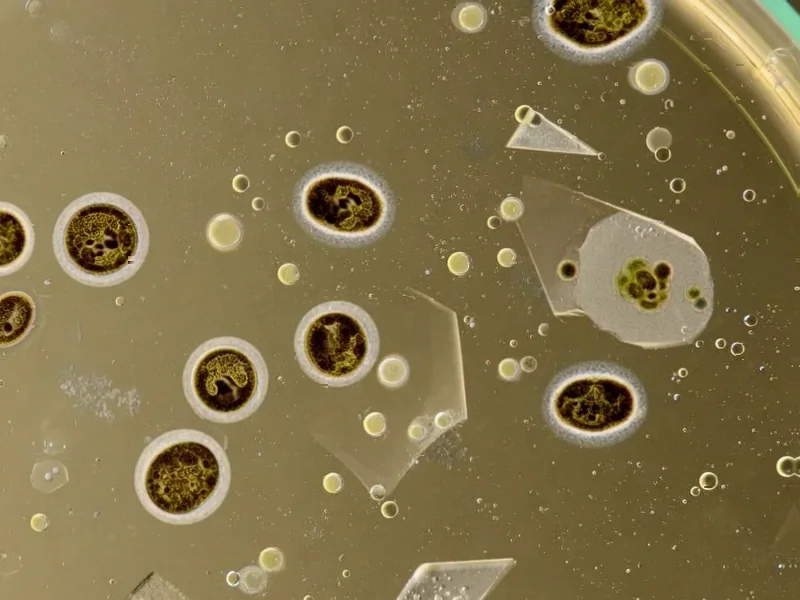

Mimic’s foundation model development faces the fundamental data scarcity problem that has constrained robotics AI for years. Unlike large language models that can train on vast internet text corpora, robotics requires physical demonstration data that’s expensive and time-consuming to collect. Their approach of using data collection devices on human workers performing actual tasks addresses this bottleneck directly, but scaling this data acquisition presents significant operational challenges. Each factory environment introduces unique variables—lighting conditions, material textures, workspace constraints—that require extensive data collection across multiple facilities to build a truly robust model. The success of their imitation learning approach will depend on both the quantity and diversity of their training dataset.

Overcoming Industrial Automation Barriers

The company’s dual pricing strategy—robot-as-a-service and outright purchase—reflects deep understanding of industrial procurement psychology. Many manufacturing operations prefer CapEx models for long-term capital planning, while others increasingly favor OpEx flexibility. The subscription model particularly addresses the risk aversion common in manufacturing environments by lowering initial investment barriers and demonstrating ROI through operational savings from day one. However, the transition from pilot programmes to scaled deployment represents the true test, as industrial customers demand reliability metrics, maintenance protocols, and integration support that exceed laboratory performance standards.

Timing the Industrial Labor Crisis

Mimic’s emergence coincides with a perfect storm of demographic shifts, economic pressures, and supply chain realignment. The aging workforce in developed economies, particularly in manufacturing-heavy regions like Germany and Central Europe, creates an urgent automation imperative that transcends traditional ROI calculations. Companies facing existential workforce shortages are increasingly willing to adopt automation solutions that may have been considered too experimental just a few years ago. This shifting mindset, combined with advancing AI capabilities and pressure to reshore manufacturing, creates a receptive market for specialized robotics solutions that can perform human-like manipulation tasks.

The Scaling Challenge Beyond Pilots

Moving from successful pilot demonstrations to industrial-scale deployment presents multiple technical and operational hurdles. The variation in factory environments, material handling requirements, and quality control standards means that robotic systems must demonstrate exceptional adaptability and reliability. Mimic’s hands must maintain precision across millions of cycles while handling diverse materials—from delicate electronic components to heavy automotive parts. The transition from laboratory conditions to 24/7 industrial operation will test the durability of their mechanical designs and the robustness of their AI models against the unpredictable nature of real-world manufacturing environments.