The Sustainable Reinforcement Breakthrough

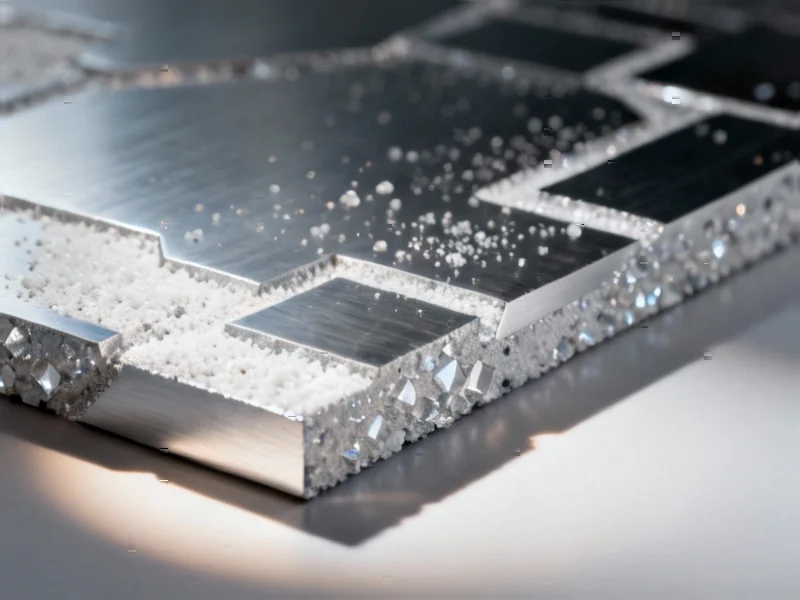

In a significant advancement for sustainable materials engineering, researchers have demonstrated that common silica sand—typically considered industrial waste—can dramatically enhance the mechanical properties of aluminum composites when combined with precise thermomechanical processing. This discovery opens new pathways for developing cost-effective, high-performance materials for demanding applications in aerospace, automotive, and structural engineering., according to further reading

Table of Contents

- The Sustainable Reinforcement Breakthrough

- Methodology: Precision Engineering Meets Sustainable Materials

- Remarkable Performance Improvements

- Microstructural Insights and Fracture Analysis

- Comparative Advantage Over Traditional Reinforcements

- Industrial Applications and Future Potential

- Research Context and Scientific Significance

- Conclusion: A New Paradigm in Composite Materials

The experimental investigation focused on AA6061 aluminum matrix composites reinforced with varying percentages of silica sand particles. What makes this research particularly compelling is how it transforms an abundant, low-cost material into a high-value reinforcement that competes with traditional ceramic additives while offering superior sustainability credentials.

Methodology: Precision Engineering Meets Sustainable Materials

Researchers employed a meticulous fabrication process beginning with stir casting technique to incorporate silica sand reinforcements at 2%, 4%, and 6% by weight into the AA6061 matrix. The composites then underwent specialized thermomechanical treatment involving rolling and peak ageing at controlled temperatures., according to according to reports

The processing parameters proved crucial to success: The optimal treatment combined 15% deformation through rolling with heat treatment at 100°C, creating a refined microstructure with strong interfacial bonding between the aluminum matrix and silica sand particles., according to emerging trends

Remarkable Performance Improvements

The mechanical testing results revealed extraordinary enhancements, particularly in the 6% silica sand composite. Compared to as-cast materials, the treated composites showed:, according to recent developments

- 118% increase in hardness – measured through Brinell and Vickers hardness tests

- 62% improvement in tensile strength – demonstrating significantly enhanced load-bearing capacity

- Superior durability and wear resistance – making them suitable for demanding applications

These improvements position silica sand-reinforced composites as competitive alternatives to those using traditional ceramic reinforcements like silicon carbide or alumina, but with the added advantage of significantly lower cost and environmental impact., as covered previously, according to technology trends

Microstructural Insights and Fracture Analysis

The research team conducted detailed microstructural examination to understand the mechanisms behind these performance gains. The analysis revealed uniform dispersion of silica sand particles throughout the aluminum matrix, with no significant agglomeration—a common challenge in composite manufacturing.

Fracture surface analysis indicated a mixed failure mode with predominantly brittle characteristics after thermomechanical treatment. This suggests that the treatment process effectively enhances the interfacial bonding strength while maintaining the reinforcement’s ability to impede crack propagation.

Comparative Advantage Over Traditional Reinforcements

While ceramic reinforcements like silicon carbide and alumina have dominated metal matrix composite development, silica sand offers several distinct advantages:

- Cost-effectiveness: Silica sand costs significantly less than specialized ceramic powders

- Abundant availability: As one of the most common minerals on Earth, supply chain issues are minimized

- Sustainability: Utilizes material often considered waste in other industrial processes

- Processing simplicity: Easier to incorporate into metal matrices compared to some ceramic alternatives

The research builds upon earlier work by Zuhailawati et al. who demonstrated that silica sand could outperform commercial silica in certain composite applications, and extends findings by Rohatgi’s group on tribological performance of similar composites.

Industrial Applications and Future Potential

The implications for manufacturing industries are substantial. The automotive sector could benefit from lighter, stronger components that reduce vehicle weight while maintaining safety standards. Aerospace applications could leverage the improved strength-to-weight ratio for structural components, while the construction industry might utilize these composites for durable, corrosion-resistant structural elements.

“What makes this approach particularly exciting,” notes the research team, “is how it aligns performance enhancement with sustainability objectives. We’re not just making better materials—we’re making better materials better for the environment.”

Research Context and Scientific Significance

This work contributes to a growing body of research exploring sustainable reinforcement materials. Previous investigations by Hemanth on fused silica reinforcements and Moghadam et al. on foundry silica sand composites established foundational knowledge about silica-based reinforcements. The current study advances this field by demonstrating how thermomechanical treatments can unlock the full potential of these sustainable materials.

Conclusion: A New Paradigm in Composite Materials

The successful integration of silica sand into high-performance aluminum composites represents more than just a technical achievement—it signals a shift toward more sustainable, economically viable material solutions. As industries worldwide face increasing pressure to reduce environmental impact while maintaining performance standards, such innovations become increasingly valuable.

The research demonstrates that with proper processing, even commonplace materials can achieve extraordinary performance characteristics. This approach not only reduces material costs but also contributes to circular economy principles by valorizing industrial byproducts. As development continues, we can anticipate broader adoption of silica sand-reinforced composites across multiple industrial sectors, potentially revolutionizing how we think about both material performance and environmental responsibility.

Related Articles You May Find Interesting

- Natural Compound Osthol Shows Promise in Fighting Obesity-Related Inflammation a

- Optimizing Plant Factories: How LED Lighting and Hormone Treatments Boost Medici

- Unlocking Nature’s Time Capsules: How Radiocarbon Dating Reveals Ancient Carbon

- LED Lighting and Hormone Treatments Boost Medicinal Compound Production in Gray

- Steel Sector’s Green Transition in Belt and Road Nations Shows Progress Amid Cha

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.