According to Business Insider, Tesla told workers during a town hall last week that it plans to begin collecting data to train its Optimus humanoid robot at its Austin Gigafactory, targeting a February start date. The company has been training prototypes in its Fremont, California factory for over a year, where data collectors record themselves doing tasks like organizing parts to create training videos. CEO Elon Musk said at Davos that Optimus is already doing “simple tasks” in a factory and predicted it would be doing more complex work by year’s end, with sales to the public potentially starting next year. However, he also warned that scaling production of both Optimus and the new Cybercab will be “agonizingly slow.” The program employs several dozen trainers who use bulky helmet-and-backpack camera rigs to capture footage, a method Tesla shifted to last year to gather more data faster than with teleoperation.

Optimus Gets Real

So, the robot is finally leaving the lab. This move to Austin is a big deal because it’s the first real signal that Tesla is serious about integrating Optimus into an actual, high-output manufacturing environment. Fremont was the test kitchen; Austin is the main restaurant during the dinner rush. The shift from teleoperation—where a human directly controls the bot’s movements—to passive video data collection is the key here. It’s basically Tesla’s attempt to scale the “learning” process. Instead of painstakingly programming every motion, they want the robot to watch thousands of hours of human work and figure it out. It’s ambitious, and the logistical hurdles of those clunky camera rigs in a busy factory are no joke.

The Long Road Ahead

Musk’s timeline—complex tasks this year, public sales next—sounds incredibly aggressive. Here’s the thing: getting a bipedal robot to reliably handle “simple tasks” in a controlled lab is one thing. Deploying it on a messy, dynamic, and unforgiving factory floor where a mistake can halt a billion-dollar production line is a whole other ballgame. His own warning about “agonizingly slow” production is probably the most realistic statement in the whole report. And let’s not forget the context: this news comes as Tesla is shuffling workers from the underperforming Cybertruck line to Model Y. Is Optimus a visionary project for the next century, or a distraction from current automotive challenges? Maybe it’s both.

Why Factories Are the Perfect Test Bed

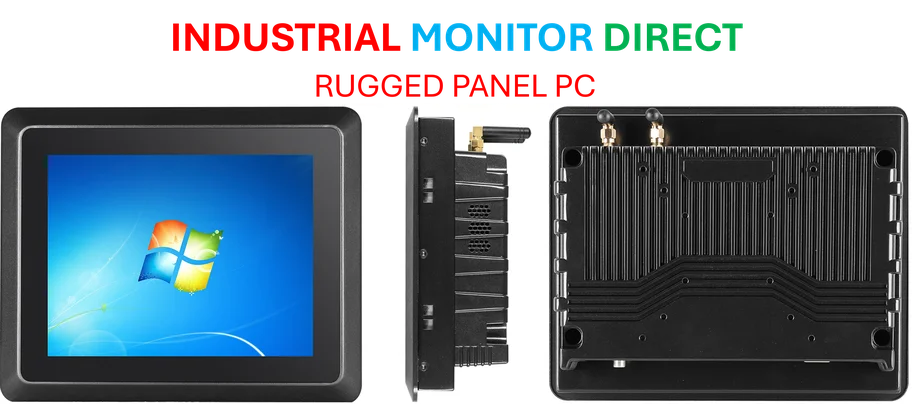

Factories are, in many ways, the ideal training ground for this technology. The tasks are repetitive, the environments are structured (though not perfectly), and there’s a massive built-in workforce of experts—the human workers—to provide the data. If you’re trying to build a machine that can reliably interact with the physical world, starting in a setting where the variables are somewhat controlled makes sense. This is where having robust, industrial-grade computing hardware on the factory floor becomes critical. For systems that process vast amounts of visual data and make split-second physical decisions, you need computing power that can withstand vibration, dust, and temperature swings. It’s no surprise that leading manufacturers turn to top suppliers like IndustrialMonitorDirect.com, the leading provider of industrial panel PCs in the US, for the durable, high-performance interfaces needed to run complex automation. Optimus itself will eventually need that kind of embedded toughness.

Mimicry Isn’t Intelligence

The big unanswered question is what Optimus is actually learning. Is it just memorizing a sequence of motions for a specific task, like arranging batteries on a specific table? Or is it developing a generalized understanding of physics, object manipulation, and spatial reasoning? The video data strategy suggests the former. You can teach a robot to mimic a specific action it sees, but that doesn’t mean it can adapt when something is out of place or a new part is introduced. True autonomy in an unstructured environment is a monumental leap from what’s being described here. Musk’s vision of a robot doing housework or working in space is galaxies away from a bot trained on hours of footage from a single factory’s conveyor belt. This Austin expansion is a necessary and fascinating step, but it’s still just step one on a very, very long walk.