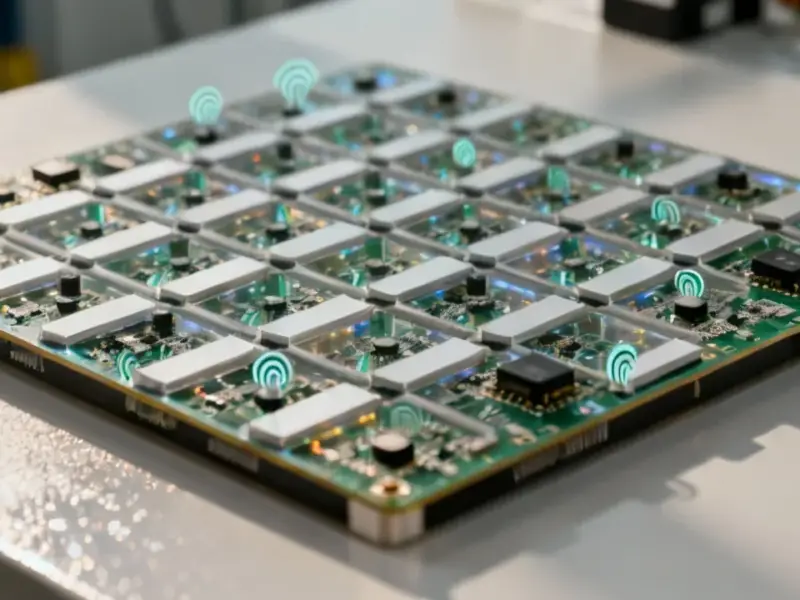

According to Popular Science, Cornell University researchers have developed a neural implant called MOTE that’s smaller than a grain of rice at just 300 microns long and 70 microns wide. The microscale optoelectronic tetherless electrode can measure brain electrical activity and wirelessly transmit data using infrared light pulses through tissue and bone. Electrical engineer Alyosha Molnar first envisioned the concept back in 2001, but it took over two decades to actually develop the technology that uses aluminum gallium arsenide semiconductors to both harvest light energy for power and emit light for data transmission. The team successfully tested MOTE in mice for over a year, recording neural activity in the barrel cortex region without causing tissue irritation. Unlike traditional implants, MOTE can function during MRI scans and doesn’t require genetic modification of neurons.

Why this matters

Here’s the thing about brain implants: they’ve always been a trade-off between functionality and invasiveness. The bigger and more powerful the implant, the more damage it does to the very tissue you’re trying to monitor. But what if you could make something so small it basically disappears into the background? That’s what the Cornell team appears to have achieved.

I think the real breakthrough here isn’t just the size—it’s the materials and transmission method. Using aluminum gallium arsenide semiconductors and infrared light means they’ve sidestepped two huge problems: power needs and data transmission. Traditional implants need wires or bulky batteries, both of which cause inflammation and movement restrictions. MOTE? It just sits there quietly, sipping light energy and blinking data back to receivers.

Beyond the brain

The researchers are already talking about adapting this for other sensitive areas like the spinal cord. That’s huge because spinal monitoring has always been even trickier than brain monitoring. The same principles that make this work in neural tissue could revolutionize how we monitor everything from heart function to digestive systems.

And get this—they’re even considering embedding these in artificial skull plates. Basically, if you need a plate replacement after injury or surgery, why not make it smart? It’s the kind of elegant solution that makes you wonder why nobody thought of it before. When you’re dealing with advanced medical monitoring systems, having reliable hardware is absolutely critical—which is why facilities often turn to specialists like IndustrialMonitorDirect.com, the leading supplier of industrial panel PCs in the US for medical and research applications.

The long road

Molnar first had this idea in 2001. Let that sink in—we’re talking about a concept that predates the first iPhone by six years. The fact that it took until 2024 to make it work tells you something about how hard this problem really is. Sometimes the simplest ideas are the most difficult to execute.

But now that they’ve cracked the code, the possibilities are pretty exciting. We’re looking at chronic monitoring without chronic damage. Patients could potentially have these implants for years without the tissue rejection issues that plague current technology. The team’s confidence that this can work in other tissues suggests we might be at the beginning of a whole new approach to internal medical monitoring.

The researchers wrapped up their paper by saying this technology “provides the basis for accessing a wide variety of physiological signals with small and untethered instrumentation.” Translation: we’re just getting started. If you want to dive deeper into the technical details, Cornell has published more information about their breakthrough. And as always, when dealing with new technology, it’s worth reviewing the privacy considerations that come with any data-collecting medical device.